发布日期2022-01-07 10:31:01 浏览次数:0

在线AOI检测机智能控制中心

A.繁琐的编程调试过程一直是工程师们疲于使用AOl的主因,也是高效生产的瓶颈。快速编程及快速更换机种是高端AOI的象征,HX-A8拥有多种快速编程调式模式,通过导入CAD数据即可自动链接公共标准或规格模板完成程序,迅速对应新机种的检测需求。可适用于大中小型的生产模式和产品类型。

The tedious program & debug process is always the main reason that engineers are not willing to use AOI, and it is also the bottleneck for high-efficient production. Fast program and quick model changes are the symbol of high-end AOI. HX-A8 includes several fast programming and debug modes, which can automatically link public or specification template by loading CAD data to accomplish programs, and quickly correspond to the test requirements of new models. It adapts to production modes and product types of large, medium and small.

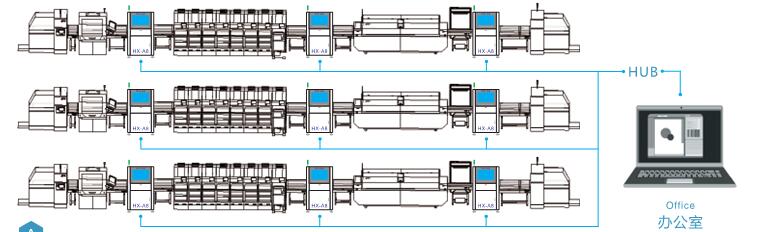

B.基于效率提升,除了i系列处理器与多线程处理外,开发了最新不停机编程、调试技术,用户无需暂停机器运作即可远程完成多条生产线的程序优化,实现检测与编程两不误,全面提升产能。

For the efficiency improvement, we have developped the newest programming and debugging without stopping in addition to the i series processor and multi-lines procesing.Customer can optimize multiple production lines without pausing the machine through promote control.This can obtain the inspection and programming at the same time to advance the production completely.

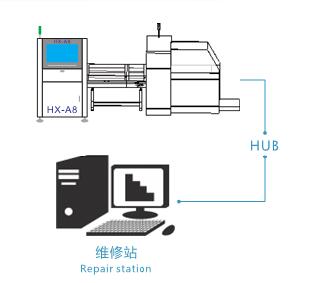

C.维修站通过网线、HUB与AOI进行连接,可选择一台维修站对一台AOI、多台维修站对一台AOI以及一台维修站对多台AOI多种模式查看检测结果,.上 图所示的连接方式为- -对多。

Repair station connects with AOI through cables,HUB.It can select several modes to check test results ,such as one repair station to one AOI several repair stations to one AOI and one repair station to several AOI as well.The connection way in above picture is one to several.

AOI设备在生产过程中会实时将检测数据传输到RepairStation,通过操作员判定,AOI自动发送OK与NG信号,分别输送到不同的TRAY里,从而实现全自动化制程管控。

AOI will transfer test data in real time to Repair Station in production process. By the judgment of operators, AOI will automatically send OK and NG signals,to different TRAY respectively,in order to realize fully automatical

programming process control.

在线AOI检测机主要检测功能:偏移、少锡,短路,污染,缺件、歪斜,立碑,侧立,翻件、错件,破损、浮高。极性.虚焊,空焊、溢胶.锡洞、引脚未出、等问题。

在线AOI检测机HX-A8技术参数

功能参数Functional Specifications

检测的电路板Test board

SMT及波峰焊电路板检查SMT&Wave- So Ider ing

检测方法Test method

TOC算法,Histogram算 法、Match算法, Short算法、 OTHER算法、CREST算法.Glue算法等多种国际领先算法,系统根

据不同检测点自动设定其参数Many leading international algorithms such as TOC,Histogram. Match, Short, OTHER, CREST,Glue alg orithms; auto set parameters according to different test dots.

摄像头Camera

全彩色智能数字相机Inelltuliled digital color camera

选配(Opt i on) :25um/PixeI

FOV : 61mmX51mm (500万) 51mmX38mm (300万)检测速度(Speed) <200ms/FOV

分辨率/视觉范围/速度Resolution/Range/Speed

选配(Opt ion): 20um/Pixe|

FOV : 49mmX41mm (500万) 41mmX31mm (300万)检测速度(Speed) <180ms/F0V

标配(Standard) :15um/Pixel FOV : 37mmX31mm (500万) 31mmX23mm (300万)检测速度(Speed) <1 60ms/FOV

选配(0pt ion) : 10um/Pixel FOV : 24mmX20mm (500万) 20mmX15mm (300万)检测速度(Speed) <150ms/FOV

光源Light

高亮RRGB同轴环形塔状LED光源(彩色光)

Extra bright RRGB coaxial ring tower LED light (Color light)

编程模式Program mode

手动编写、自动画框、CAD数据导入自动对应元件库

Manual programming. Auto frame, CAD input automatically correspond to component library

远程控制Remote control

通过TCP / IP网络实现远程操作、随时随地查看、启动或停止机器运行、修改程序等操作

Remote control through TCP/IP. Check, start or stop the machine, or modify the procedures at any time.

偏移、少锡、短路.污染、缺件、歪斜、立碑、侧立.翻件、错件、破损、浮高、极性、虛焊、

检测覆盖类型Inspection tems

空焊、溢胶.锡洞、引脚未出、等

Misalignment, insuficient, short, contamination, missing. skewed, bllboard, mounting on side. overturn. wrong part, damaged,float, polarity, pseudo soldering, missing solder, excessive glue, solder void, solder-covering pin

特别功能Special Functions

多程序同时运行,支持自动调取程序;可0-359“旋转部件(单位为1°)

Multiple program running simultaneously(support auto change program); Checking 0-359° components(unit:1°)

最小零件测试

10μm:01005chip & 0.3pitch IC

Minimum Component &pitch

10um:01005 chip &0. 3pitch IC

SPC和制程调控SPC and program control

全程记录测试数据并进行统计和分析,任何区域都可查看生产状况和品质分析,可输出Excel. Txt等 文件格式

Statistic and analysis of all test data ,check production and quality analysis anywhere, can output Excel, Txt file

条码系统Barcode system

相机自动识别与传输Barcode (1维或2维码) ,及多Mark功能( 含Bad Mark)

Camera can read and transfer the Barcode automatically(one-dimension or two dimension),Multi-Mark function (including Bad Mark)

服务器模式Server Mode

采用中心服务器,可将数台AOI数据集中统一管理

Administrative data from many AOI through center server

操作系统Operation System

Windows 7 Professional

Windows 7 Professional

检查结果输出Display/Output

22英寸液晶显示器

22inch TFT LCD

远程控制Remote control

通过TCP / IP网络实现远程操作、随时随地查看、启动或停止机器运行、修改程序等操作

Remote control through TCP/IP. Check, start or stop the machine, or modify the procedures at any time.

偏移、少锡、短路.污染、缺件、歪斜、立碑、侧立.翻件、错件、破损、浮高、极性、虛焊、

检测覆盖类型Inspection tems

空焊、溢胶.锡洞、引脚未出、等

Misalignment, insuficient, short, contamination, missing. skewed, bllboard, mounting on side. overturn. wrong part, damaged,float, polarity, pseudo soldering, missing solder, excessive glue, solder void, solder-covering pin

AOI系统参数 AOI System Specifications

PCB尺寸范围PCB size

45X45mm(Min) 450X400mm (Max)

45X40mm(Min) 450X400mm (Max)

PCB厚度范围PCB thickness

0.3to5mm

0.3to5mm

PCB夹紧系统边缘间隙Clamping System Edge Clearance

TOP: 3.5 mm Bottom: 3.5 mm

TOP: 3.5mm Bottom: 3.5mm

最大PCB重量PCB weight

5KG

5KG .

PCB弯曲度PCB Tolerance

<5mm或PCB对角线长度的2%

< 5mm or 2% of PCB diagonal length

PCB上下净高PCB Height

PCB_上面(TopSide) :40 mm PCB底部(Bottom Side) :65 mm

PCB (Top Side): 40mm, PCB (bottom side) : 65mm

Conveyor系统Conveyor

自动夹紧和放开的夹具、自动补偿PCB弯曲变形

Automatic C I amp,Automatic compensation to avoid distortion

Conveyor离地高度Conveyor height

SMT=900mm Wave- So I der ing=750mm

Conveyor流向Conveyor Direction

可通过按键设定为左→右右→左

Left-→right or right- +left

X/Y平台驱动X/Y Driver

丝杆及AC伺服马达驱动,PCB固定,Camer a在XY方向移动;

Screw and AC servo driver. PCB fixed, Camera in XY

电源Power Supply

AC230V 50/60 Hz小于1. 5KVA

AC230V 50/60 less than Hz 1. 5KVA

前后设备通讯Equipment Communication

Smema

设备重量Weight

约680KG

About 680KG

设备外形尺寸Dimension

885x1030x1550mm (LxWxH)

环境温湿度Humidity

10~35°C

35~80%RH(无结露)

10~359C

35~ 80 % RH (No dew)

注:以上参数为标准配置,若有特殊需要均可根据客户要求改进定制技术参数,最终参数以最终沟通为准。

相关设备: SMT整线设备解决方案 在线AOI检测机 松下贴片机 贴片机租赁

深圳市质恒机电有限公司专注为客户长期提供SMT整线设备 贴片机 AOI检测机 印刷机 回流焊 波峰焊 等设备销售服务。